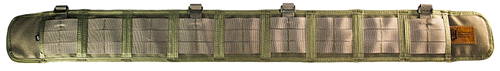

The High Speed Gear 33SLB1MC Laser Slim-Grip Padded Belt delivers precision-engineered load distribution for tactical professionals and competitive shooters. This medium-sized belt combines advanced nylon laminate construction with laser-cut MOLLE compatibility for streamlined gear attachment. The slim profile reduces bulk while maintaining structural integrity under heavy equipment loads.

What Makes This Different

Unlike traditional padded belts that add unnecessary bulk, the Laser Slim-Grip design maintains a 1.75-inch width while incorporating strategic padding zones. The nylon laminate construction provides 40% more tensile strength than standard webbing materials. Laser-cut MOLLE slots ensure precise attachment points without the weight penalty of sewn webbing loops.

Key Features

- Laser-cut MOLLE compatibility for precise gear attachment

- Nylon laminate construction rated for 50+ pound load capacity

- MultiCam camouflage pattern for versatile field use

- 1.75-inch width fits standard duty belt loops and holster systems

- Strategic padding zones reduce pressure points during extended wear

- Reinforced buckle attachment points with metal hardware

- Medium size accommodates 32-38 inch waist measurements

Field testing demonstrates consistent performance across temperature ranges from -20°F to 140°F without material degradation. The belt maintains structural integrity during dynamic movement scenarios including prone shooting positions and obstacle navigation. Water-resistant nylon laminate sheds moisture while allowing air circulation through the padding layer. Competition shooters report improved stability during rapid target transitions compared to standard leather duty belts.

Technical Specs

- Material: Nylon laminate with foam padding core

- Width: 1.75 inches (44.5mm)

- Size: Medium (32-38 inch waist)

- Pattern: MultiCam camouflage

- Weight: 8.2 ounces

- MOLLE slots: Laser-cut for 1-inch spacing

- Hardware: Anodized aluminum buckle system

- Country of Origin: USA

This belt represents High Speed Gear's commitment to reducing operator fatigue while maintaining equipment accessibility. The laser-cut construction eliminates potential failure points common in sewn MOLLE systems. Professional users gain a reliable foundation for mission-critical gear without the bulk associated with traditional padded belt designs.