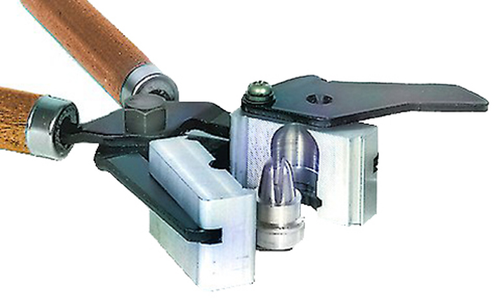

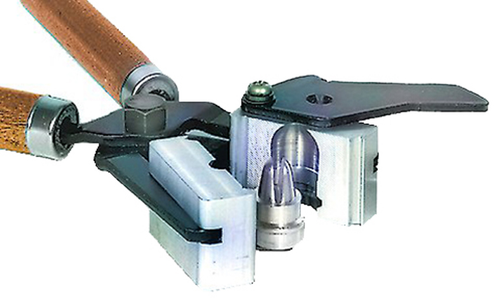

The Lee Precision 90440 delivers consistent round ball casting for black powder enthusiasts and historical firearms shooters. This aluminum mold produces two .451 caliber round balls per pour, maximizing efficiency during casting sessions while maintaining the precision Lee Precision is known for.

What Makes This Different

Unlike single-cavity molds that slow down production, this double-cavity design cuts casting time in half without sacrificing ball uniformity. The aluminum construction heats faster than iron alternatives, reaching optimal casting temperature in minutes rather than extended warm-up periods. Each cavity produces identical .451 diameter balls weighing approximately 138 grains, perfect for .45 caliber muzzleloaders and replica firearms.

Key Features

- Double cavity design produces 2 round balls per pour for increased efficiency

- Precision-machined .451 caliber cavities for consistent ball diameter

- Lightweight aluminum construction for faster heat-up times

- Integrated sprue plate with alignment pins for proper closure

- Compatible with standard bullet casting furnaces and ladles

- Produces approximately 138-grain round balls suitable for .45 caliber firearms

- Machined alignment guides ensure consistent ball-to-ball dimensions

Casting sessions become more productive with this mold's rapid cycling capability. The aluminum material reaches working temperature quickly, allowing shooters to maintain steady production rates during extended casting periods. Black powder competitors appreciate the consistent ball weight and diameter for predictable ballistic performance, while historical reenactors value the authentic round ball profile for period-correct ammunition.

Technical Specs

- Caliber: .451 diameter round ball

- Cavity count: 2 cavities per mold

- Material: Precision-machined aluminum alloy

- Ball weight: Approximately 138 grains (pure lead)

- Mold type: Hinged with integrated sprue plate

- Compatibility: Standard casting furnaces and ladles

- Manufacturer: Lee Precision, USA

This mold addresses the time constraints faced by active shooters who need substantial quantities of round balls for practice and competition. The double-cavity configuration and quick-heating aluminum construction combine to deliver professional-grade results without the extended setup times associated with traditional iron molds.