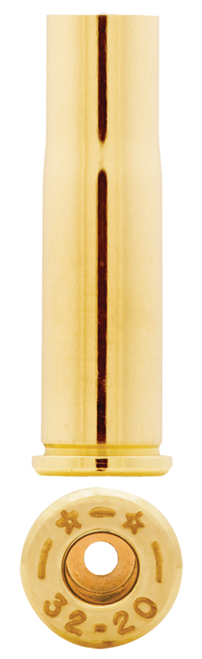

The Starline Brass 32SWLEUP100 delivers consistent wall thickness and precise dimensions for reliable 32 S&W Long ammunition production. Starline's manufacturing process creates brass cases that maintain structural integrity through multiple reloading cycles while providing the dimensional accuracy competitive shooters and precision handloaders demand.

What Makes This Different

Starline brass undergoes a specialized annealing process that creates uniform hardness throughout each case wall. This controlled manufacturing approach produces cases with consistent neck tension and primer pocket dimensions that exceed SAAMI specifications. The brass composition maintains optimal elasticity for reliable extraction while resisting case head separation during high-pressure loads.

Key Features

- 100 unprimed 32 S&W Long brass cases per bag

- Uniform wall thickness within 0.001" tolerance

- Small pistol primer pocket sized to 0.175" diameter

- Case length held to 0.920" ± 0.005" specification

- Annealed neck area for consistent bullet seating

- Flash hole deburred and centered for uniform ignition

- Compatible with standard 32 S&W Long load data

These cases handle both light target loads and maximum SAAMI pressure loads without case failure. Competition shooters rely on the consistent neck tension for uniform bullet release and improved accuracy potential. The brass accepts standard small pistol primers and works with all major powder manufacturers' load data for the 32 S&W Long cartridge.

Technical Specs

- Caliber: 32 S&W Long

- Case length: 0.920 inches

- Rim diameter: 0.383 inches

- Case mouth diameter: 0.337 inches

- Primer type: Small pistol

- Material: 70/30 brass alloy

- Package quantity: 100 cases

- Country of origin: United States

Starline's quality control process ensures each case meets dimensional specifications before packaging. The brass arrives ready for powder charging and bullet seating without additional case preparation steps required for most reloading applications.