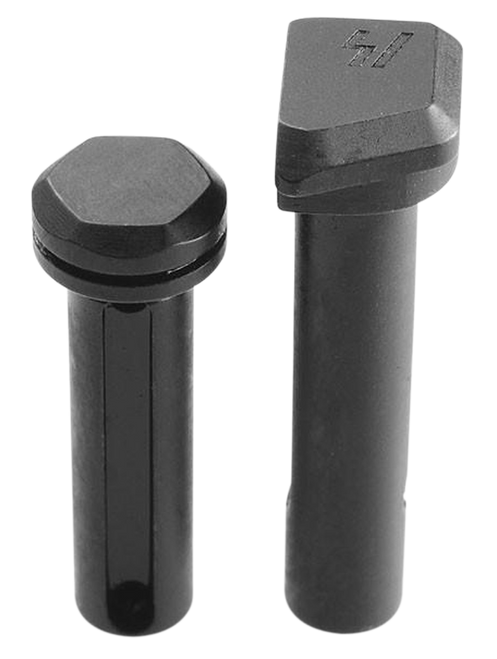

The Strike Industries AREPTPGC Extended Takedown/Pivot Pins eliminate the frustration of standard pins that require tools or fall out during field stripping. These oversized pins feature enlarged heads that allow finger manipulation without punches or tools, streamlining maintenance and assembly procedures.

What Makes This Different

Unlike standard mil-spec pins that require hammer and punch sets, these extended pins incorporate oversized heads measuring 0.375 inches in diameter. The additional surface area provides positive grip even with wet or gloved hands. Gold titanium nitride coating delivers superior corrosion resistance compared to standard phosphate finishes while maintaining the precise 0.2500-inch shaft diameter required for proper fit.

Key Features

- Enlarged 0.375-inch diameter heads enable tool-free installation and removal

- 4140 steel construction with gold titanium nitride coating for durability

- Maintains mil-spec 0.2500-inch shaft diameter for proper receiver fit

- Compatible with AR-15, M4, and M16 platform receivers

- Knurled grip surfaces prevent slipping during manipulation

- Heat-treated steel core rated for repeated cycling

- Retains standard spring and detent functionality

Field stripping becomes a 30-second operation instead of requiring a cleaning kit. The extended heads provide sufficient leverage to overcome spring tension without tools, making these pins valuable for competitive shooters who need rapid disassembly between stages. The titanium nitride coating resists wear from repeated use while the gold finish aids in quick visual identification during low-light conditions.

Technical Specs

- Material: 4140 steel with titanium nitride coating

- Head diameter: 0.375 inches

- Shaft diameter: 0.2500 inches (mil-spec)

- Overall length: Standard mil-spec dimensions

- Finish: Gold titanium nitride

- Compatibility: AR-15, M4, M16 platforms

- Package: Set of 2 pins (takedown and pivot)

- Country of origin: USA

These pins represent a practical upgrade that reduces maintenance time while maintaining reliability standards. The investment pays dividends through faster cleaning cycles and elimination of lost pins during field stripping operations.