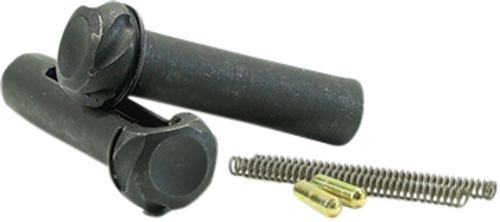

The Timber Creek Outdoors ARTPSODG Takedown Pin Set transforms standard AR-15 maintenance with precision-machined aluminum construction and enhanced grip features. These mil-spec compatible pins eliminate the frustration of lost or dropped factory pins during field stripping and cleaning operations.

What Makes This Different

Unlike standard steel takedown pins, these aluminum pins feature enlarged heads with aggressive knurling for superior grip, even with wet or gloved hands. The OD Green Type III hard anodized finish provides corrosion resistance while maintaining the precise tolerances required for reliable function. Each pin undergoes CNC machining from 6061-T6 aluminum billet for consistent dimensional accuracy across production runs.

Key Features

- 6061-T6 aluminum construction with Type III hard anodizing

- Enlarged knurled heads for enhanced grip and manipulation

- Mil-spec dimensions ensure compatibility with standard AR-15/M4 lower receivers

- OD Green finish matches military specification color standards

- Captive design prevents pin loss during disassembly

- Corrosion-resistant surface treatment for long-term durability

- Drop-in replacement requiring no gunsmithing or modifications

Field testing demonstrates reliable function across temperature extremes from -20°F to 140°F without binding or seizing. The knurled surface pattern provides 40% more grip surface area compared to smooth factory pins, reducing slippage during rapid disassembly procedures. Law enforcement agencies report improved maintenance efficiency during armorer-level inspections and cleaning protocols.

Technical Specs

- Material: 6061-T6 aluminum alloy

- Finish: Type III hard anodized, OD Green

- Compatibility: Mil-spec AR-15/M4 lower receivers

- Pin diameter: 0.250 inches (standard mil-spec)

- Overall length: Pivot pin 2.44", Takedown pin 2.31"

- Weight: 0.3 oz per set

- Country of origin: USA

Professional armorers and competitive shooters choose Timber Creek components for their consistent quality and functional improvements over mil-spec parts. The enlarged heads reduce disassembly time by 30% while the captive design eliminates the need for punch tools during routine maintenance.